Naiad Dynamics US, Inc.

PRECISION MANUFACTURING

Naiad Dynamics US, Inc.

PRECISION MANUFACTURING

PRECISION MANUFACTURING

PRECISION MANUFACTURING

Founded in 1941 as a manufacturer for military components, Van Dusen & Meyer, Inc. (today, Naiad Dynamics US, Inc.) has grown to become a leading supplier of precision machined parts for a wide variety of military and commercial industries—including aerospace, naval & commercial marine, medical, nuclear, and machine tool. Naiad Dynamics has earned a reputation for exceptionally high quality work, delivered on time and at the lowest possible cost.

In addition to our manufacturing services, Naiad Dynamics produces state-of-the-art marine motion control equipment and integrated hydraulic power systems for the luxury yacht, military and commercial ship markets. We have reliably supplied 55 of the world's navies, most of the world's fast ferries, and more luxury yachts than any other manufacturer in its equipment sector. For more information on our marine products, visit our web site at www.naiad.com

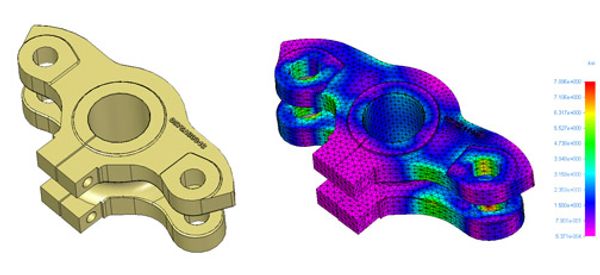

Full engineering design and R&D team to help advance your next component part, machine design, concept, or hydraulic system. Our experienced in-house staff utilizes the latest 2D and 3D CAD, Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) software to provide efficient, practical designs. Full confidentiality and protection of customer’s proprietary information.

Since 1941, Naiad Dynamics has grown into a leading supplier of precision machined parts for a wide variety of military and commercial industries incluuding aerospace, naval & commercial marine, medical, nuclear and machine tool. Clients include the U.S Department of Defense, United Technologies/Sikorsky Aircraft, General Dynamics/Electric Boat, Lockheed Martin/Sippican, Northrop Grumman/Norden Systems and Raytheon, to name only a few.

Naiad Dynamics US, Inc. operates in a clean and organized 30,000 square foot facility located in Shelton, Connecticut - 45 miles south of Hartford and 60 miles north of New York City. We specialize in manufacturing challenging components designed to meet the demanding requirements of the aerospace, defense, medical and marine products industries. We routinely collaborate with customers on product developments to improve quality and lower cost.